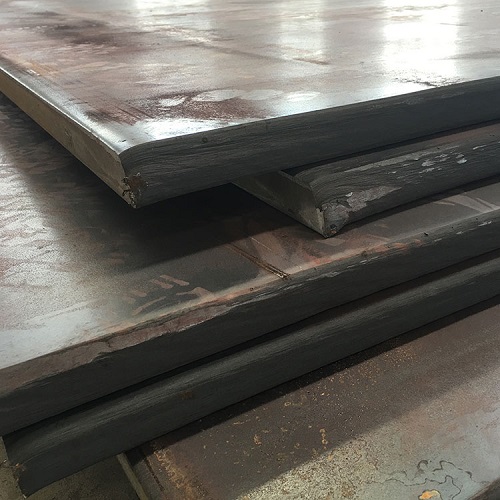

Iipleyiti zentsimbi ezikwaziyo ukunxiba:

(1) I-NM360 (i-360 enganxibi)

Ukuthiywa: U-N kukuxhathisa (nai) U-M ngunobumba wokuqala we-pinyin weempawu ezimbini zesiTshayina zokusila (mo), kwaye i-360 imele ubulukhuni be-Brinell beli cwecwe zentsimbi.

Unyango lobushushu: ubushushu obuphezulu, ukucima + ubushushu (ukucima kunye nobushushu)

Isicelo: I-NM360 yentsimbi enganyangekiyo isetyenziswa kakhulu koomatshini bemigodi, oomatshini bemigodi yamalahle, indalo esingqongileyo.

Ikwasetyenziswa ngokuqhelekileyo njengentsimbi ephezulu yolwakhiwo olunamandla esivuno ≥ 700MPa.Ikakhulu kukubonelela ngokhuseleko kwizihlandlo okanye iinxalenye ezifuna ukuguga, ukwenzela ukuba izixhobo zibe nobomi obude, ukunciphisa ixesha lokugcinwa kwesondlo okubangelwa kulondolozo, kunye nokunciphisa utyalo-mali oluyinkunzi.

Ukusebenza: Isivuno singaphezulu kwe-800, kwaye amandla okuqina angaphezulu kwe-1000.

(2) NM400

I-NM400 yintsimbi ephezulu yokunxiba enganyangekiyo.I-NM400 inamandla omatshini aphezulu kakhulu;iimpawu zayo zoomatshini zi-3 ukuya ku-5 amaxesha eentsimbi eziqhelekileyo eziphantsi kwe-alloy;inokuphucula kakhulu ukuxhathisa ukunxiba kweendawo ezinxulumene noomatshini;ngaloo ndlela kuphuculwe ubomi benkonzo yoomatshini kunye nokunciphisa iindleko zemveliso.Ubunzima bomphezulu wale mveliso buhlala bufikelela kwi-360 ~ 450HB.Iipleyiti zentsimbi ezisebenzayo zokwenziwa kunye nokuveliswa kwamalungu angagugiyo kunye nasemngciphekweni wemigodi kunye noomatshini bokwakha abahlukeneyo.

I-NM400 yentsimbi enganyangekiyo isetyenziswa kakhulu koomatshini bokwakha, oomatshini bemigodi, oomatshini bemigodi yamalahle, oomatshini bokukhusela indalo, oomatshini besinyithi kunye nezinye iindawo zemveliso.Excavator, loader, bulldozer bucket plate, edge plate, side edge plate, blade.I-Crusher liners, iiblades.

(3) Mn13 (intsimbi yemanganese esemgangathweni ephezulu)

I-Mn13 yintsimbi ephezulu ye-manganese engaguqukiyo (i-HIGH MANGANESE STELL SCRAP), eyona nto ingcono kakhulu phakathi kwezixhobo zokunxiba ezifana nefuthe elinamandla kunye noxinzelelo oluphezulu lwezinto eziphathekayo.

Kukho iimpawu ezimbini ezinkulu zentsimbi ephezulu yemanganese: enye yeyokuba impembelelo yangaphandle inkulu, iphezulu ukuxhathisa ukunxiba komgangatho wayo.Xa ichaphazeleka, ubulukhuni bayo bomphezulu buya kunyuka ngokukhawuleza ukusuka kwi-HB200 ukuya ngaphezulu kwe-HB700, ngaloo ndlela ivelisa umaleko womphezulu onganxibi kakhulu.I-austenite kumqolo wangaphakathi wepleyiti yentsimbi isagcina ukuqina kwempembelelo entle;okwesibini kukuba ngokugutyungelwa kancinci komgangatho owenziwe lukhuni, iileyile ezintsha eziqinisiweyo ziya kuqhubeka nokwenza.

Ipleyiti yentsimbi eqengqelekayo ye-Mn13 inokumelana okugqwesileyo kokunxiba kwimpembelelo eyomeleleyo kunye nokunxitywa koxinzelelo oluphezulu, ayizukwaphuka ngexesha lokusetyenziswa, kwaye ineempawu zomatshini ezilula njengokusika, ukuwelda kunye nokugoba.

Intsimbi yechromium ephezulu esetyenziswa ngokwemveli inokumelana nokunxiba okufanelekileyo kuphela xa kunxitywa.I-Mn13 iplate yentsimbi eqengqelekayo inokunciphisa ngokufanelekileyo iindleko zokunxiba iinxalenye zezixhobo, ukonga iindleko zokugcina izixhobo, kunye nokuphucula ukukhuphisana kweemveliso ezigqityiweyo.

Nangona kunjalo, ukunyanzeliswa kwentsimbi ephezulu ye-manganese kubonisa ukuphakama kwayo kuphela phantsi kweemeko ezaneleyo ukwenza umsebenzi onzima, kwaye uhlwempuzekile kwezinye iimeko.

Intsimbi eqhelekileyo ye-Mn17 ekwazi ukumelana nokunxiba i-high-manganese kukunyusa inani le-manganese ngesiseko sentsimbi ye-Mn13, ephucula ukuzinza kwe-austenite kwaye ithintele imvula ye-carbides, ngaloo ndlela iphucula amandla kunye neplastiki yentsimbi kunye nokuphucula umsebenzi. ukuqina amandla entsimbi.kunye nokuxhathisa i-abrasion.Umzekelo, ubomi benkonzo yeefolokhwe zikaloliwe ze-ZGMn18 ezisetyenziswa emantla yi-20% ~ 25% ephezulu kune-ZGMn13.

Amabanga kunye nobubanzi bokusetyenziswa kwentsimbi ephezulu yemanganese esetyenziswa ngokuqhelekileyo eChina ngala: ZGMn13-1 (C 1.10%~1.50%) isetyenziselwa iindawo ezinempembelelo ephantsi, iZGMn13-2 (C1.00%~1.40%) isetyenziselwa iindawo eziqhelekileyo, i-ZGMn13- 3 (C0.90% ~ 1.30%) isetyenziselwa iindawo ezinzima, kwaye i-ZGMn13-4 (C0.90% ~ 1.20%) isetyenziselwa iindawo ezinempembelelo ephezulu.Umxholo we-manganese kula mabanga mane angentla entsimbi yi-11.0% ukuya kwi-14.0%.

Ukufakwa kwe-welding kunye nokulungiswa, i-electrodes ye-manganese-nickel esekelwe kwi-austenite (uhlobo lwe-D256 okanye i-D266) kufuneka ikhethwe, kunye nenkcazo ende kunye nencinci, i-φ3.2mm × 350mm, kunye nengubo yangaphandle i-alkaline.Indlela yokusebenza ithatha udibaniso lwe-DC reverse, i-current encinci, i-arc ebuthathaka, i-welding bead encinci kunye ne-multiple welding layers, kwaye ihlala igcina ubushushu obuphantsi kunye nobushushu obuphantsi.Betha ngelixa udibanisa ukuphelisa uxinzelelo.Uphoso olubalulekileyo kufuneka lubonwe isiphene.I-Flash welding (i-Swiss GAAS80/700 umatshini we-flash welding) okanye i-MAG welding (efana ne-Nissan YD-S-500) ingasetyenziselwa ukuwelda okubaluleke ngakumbi, enokuqinisekisa ngokufanelekileyo i-welding seam mechanical properties.

ISihlomelo 1: Ingqikelelo yobulukhuni

Ubunzima sisalathiso sokusebenza sokulinganisa ukuthamba kunye nokuqina kwezixhobo.Kukho iindlela ezininzi zokuvavanya ubulukhuni, imigaqo ayifani, kwaye amaxabiso obunzima obulinganisiweyo kunye neentsingiselo azifani ncam.Eyona nto ixhaphakileyo luvavanyo lwe-static load indentation method hardness, oko kukuthi ukuqina kweBrinell (HB), ukuqina kweRockwell (HRA, HRB, HRC), Vickers hardness (HV), irabha yeplastiki yeplastiki Ukuqina konxweme (HA, HD) kunye nobunye ubulukhuni. ukukwazi komphezulu wezinto eziphathekayo ukuxhathisa ukungena kwento enzima.Ukuqina ayisosixa somzimba esilula, kodwa sisalathiso esibanzi sokusebenza esibonisa ukuqina, iplastiki, amandla kunye nokuqina kwemathiriyeli.

Ukuqina kwentsimbi: Igama lekhowudi yobulukhuni bentsimbi nguH. Ngokweendlela ezahlukeneyo zokuvavanya ubulukhuni, kukho ikakhulu la mabinzana alandelayo.

●Amabinzana aqhelekileyo aquka uBrinell (HB), uRockwell (HRC), uVickers (HV), uLeeb (HL) ukuqina, njl., apho i-HB ne-HRC zisetyenziswa kakhulu.

● I-HB inoluhlu olubanzi lwezicelo, kwaye isetyenziswa ngokubanzi xa izinto eziphathekayo zithambile, njengezinyithi ezingenayo i-ferrous, intsimbi ngaphambi kokunyangwa kobushushu okanye emva kokutshisa.I-HRC ifanelekile kwizinto ezinobunzima obuphezulu bomhlaba, njengobunzima bonyango lobushushu, njl.

Umahluko phakathi kwezi zibini kukuba i-probes yabavavanyi bobunzima bahlukile.Iiprobes zeBrinell hardness tester ziibhola zentsimbi, ngelixa iiprobes zeRockwell hardness tester ziyidayimane.Phantsi kweemeko ezithile, i-HB kunye ne-HRC zinokutshintshwa ngokujonga phezulu kwetafile.Ifomula yayo yokubala ngengqondo inokurekhodwa ngokurhabaxa ngolu hlobo: 1HRC≈1/10HB.

● I-HV-ifanele uhlalutyo lwe-microscopic.I-Vickers hardness (HV) ixinzelelwe kumphezulu wezinto kunye nomthwalo ongaphantsi kwe-120kg kunye ne-diamond square cone indenter ene-vertex angle ye-136 °, kunye nommandla ongaphezulu womgodi wokungeniswa kwezinto uhlukaniswe ngumthwalo. ixabiso, elixabiso lobulukhuni beVickers (HV).Ubunzima be-Rockwell (HR-) buchongwa bubunzulu be-indentation deformation yeplastiki ukumisela isalathisi sexabiso lobunzima.Kulula ukuyisebenzisa, ngokukhawuleza kwaye inembile, kwaye ifanelekile kwimveliso yobuninzi.

I-Attachment 2: Isetyenziswa ngokuqhelekileyo intsimbi enganyangekiyo

Domestic (Wugang, Xingang, Wuhan Iron and Steel, Nangang, Baosteel): NM360, NM400, NM450, NM500, NR360, NR400, B-HARD360, B-HARD400, B-HARD450

Intsimbi yaseSweden ekwazi ukumelana nokunxiba: HARDOX400, HARDOX450, HARDOX500, HARDOX600, SB-50, SB-45

Intsimbi yaseJamani engagungqiyo: XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500

Intsimbi yaseBelgium engagungqiyo: QUARD400, QUARD450, QUARD500

Intsimbi yesiFrentshi ekwazi ukumelana nokunxiba: FORA400, FORA500, Creusabro4800, Creusabro8000

Intsimbi yaseFinland ekwaziyo ukunxiba: RAEX400, RAEX450, RAEX500

Intsimbi yaseJapan yokunxiba: JFE-EH360, JFE-EH400, JFE-EH500, WEL-HARD400, WEL-HARD500.

Ixesha lokuposa: Jan-29-2023