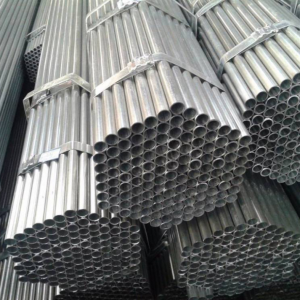

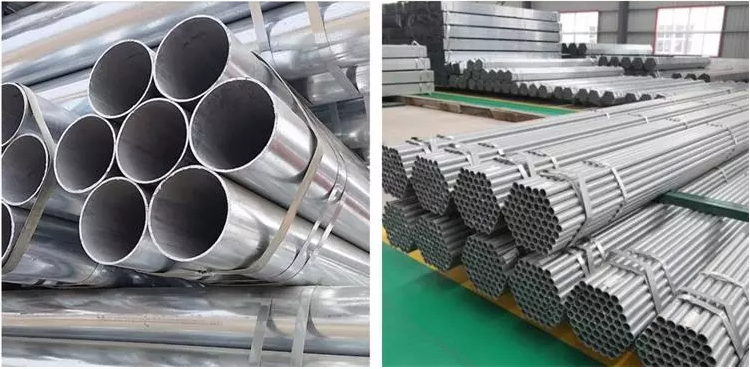

Eshushu DippedUmbhobho weNtsimbi oyiGalvanizedkukwenza isinyithi esityhidiweyo siphendule nge-matrix yentsimbi ukuvelisa umaleko we-alloy, ukwenzela ukuba i-matrix kunye ne-coating zidityaniswe.Umbhobho oDidiweyo oGqwethiweyo oshushukukuvuthela umbhobho wentsimbi kuqala.Ukuze ukususa i-iron oxide kumphezulu wombhobho wentsimbi, emva kokuchola, icocwa kwitanki ye-ammonium chloride okanye i-zinc chloride isisombululo esinamanzi okanye isisombululo esinamanzi esixutywe se-ammonium chloride kunye ne-zinc chloride, kwaye emva koko ithunyelwe Ibhafu yediphu eshushu.Umbhobho we-galvanizing we-Hot-dip uneenzuzo zokugquma okufanayo, ukunamathela okuqinileyo kunye nobomi benkonzo ende.I-substrate yemibhobho yentsimbi enezinki eshushu-dip ingena kwi-complex physical and chemical reactions kunye nesisombululo esityhidiweyo se-plating ukwenza umaleko we-zinc-iron alloy alloy-resistant kunye nesakhiwo esihlangeneyo.Uluhlu lwe-alloy luhlanganiswe ne-zinc ecocekileyo kunye ne-substrate yombhobho wensimbi, ngoko inokumelana nokugqwala okuqinileyo.

Ukupakishwa:Ibhegi engenamanzi okanye ukupakishwa kwetyala leplanga, okanye ngokwesicelo somthengi.

Ukuthumela ngenqanawe: Sinentsebenziswano yexesha elide kunye neenkampani ezininzi zokuthutha ezinamava kwaye siya kukufumanela eyona ndlela ifanelekileyo yothutho.